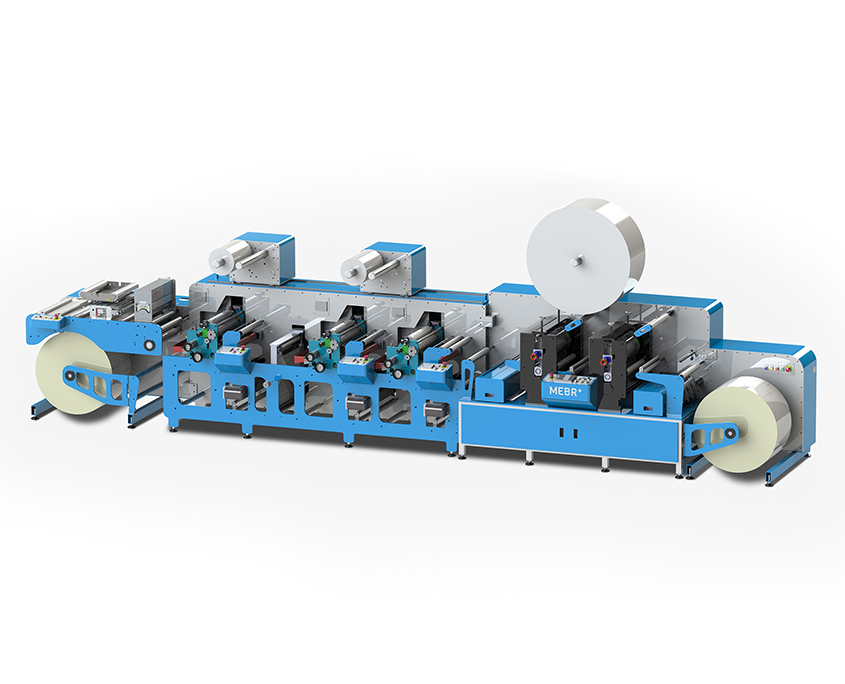

Lemorau MEBR+ Advanced I

Lemorau MEBR+ Advanced 430 mm is a modular digital finishing machine that was fully customized according to the customer needs. The machine is full servo drive equipped and the three flexo stations allow the customer print on the back, varnish and cold foil in only one single pass. With this new machine range, it enables digital printed webs to be embellished, coated and finished quickly and economically.

MACHINE FEATURES

- Maximum web width 430 mm

- Maximum semi-rotary speed 80 m/min (262,5 ft/min.) dependent on plate size

- Maximum rotary speed 120 m/min (394 ft/min.)

- Maximum unwinder diameter 800mm, servo driven, with automatic stop at master roll end

- Splice table with pneumatic clamps

- Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

- Corona treatment system

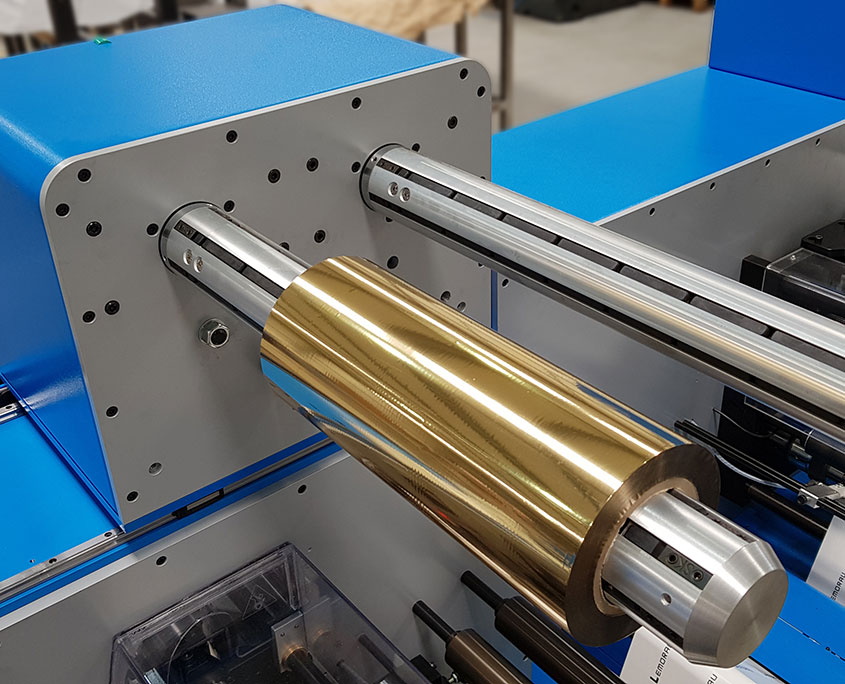

- 3 servo drive gearless UV flexo stations in register customized according to existing tools from the customer

- 2 movable cold foil/ UV lamination stations

- Turnbar which allows printing on the back on the first flexo station

- 2 die cutting stations in register customized according to existing tools from the customer

- Die cutting station number 1: semi-rotary/rotary die cut, Pressure gauges, Electronic anvil roll for adjustable gap

- Die cutting station number 2: Rotary only, Movable anvil roller to allow die cut in front and in the back in one single pass

- 1 meter waste rewinder

- Back scorer system

- Electronic Counter (Labels/ Meters/ Rolls)

- Maximum rewinder diameter 800mm, servo driven

- Deflation software for use of rotary flexible dies on the semi-rotary die cutting

- Automatic web tension control system by servo motors – Constant and Taper tension

- 250 Job memory for easy and quick job set ups

- Paper and matrix break detection

- Labels in/ labels out rewinding

- Foot pedal to jog the machine

- Multi language touch screen